ZGROUP USA, a trailblazer in modular solutions for the cold chain, successfully delivered its groundbreaking modular cooling facility to one of the largest growers of distinctive leafy greens in the U.S. This innovative turnkey solution is set to transform the cooling process for water spinach crops, addressing unique challenges and setting new industry standards.

The demand for specialty crops like water spinach has surged, requiring growers to adapt their cooling processes to maintain product freshness and quality. The current trend among growers is to bring the cooling facility as close as possible to the farm. This strategic approach allows for rapid chilling of products, significantly increasing shelf life and preserving quality from farm to table.

Traditional methods often fall short, leading to inefficiencies, compromised product integrity, and shorter shelf life. Additionally, constructing conventional cooling facilities can be cost-prohibitive and time-consuming, especially on challenging terrains.

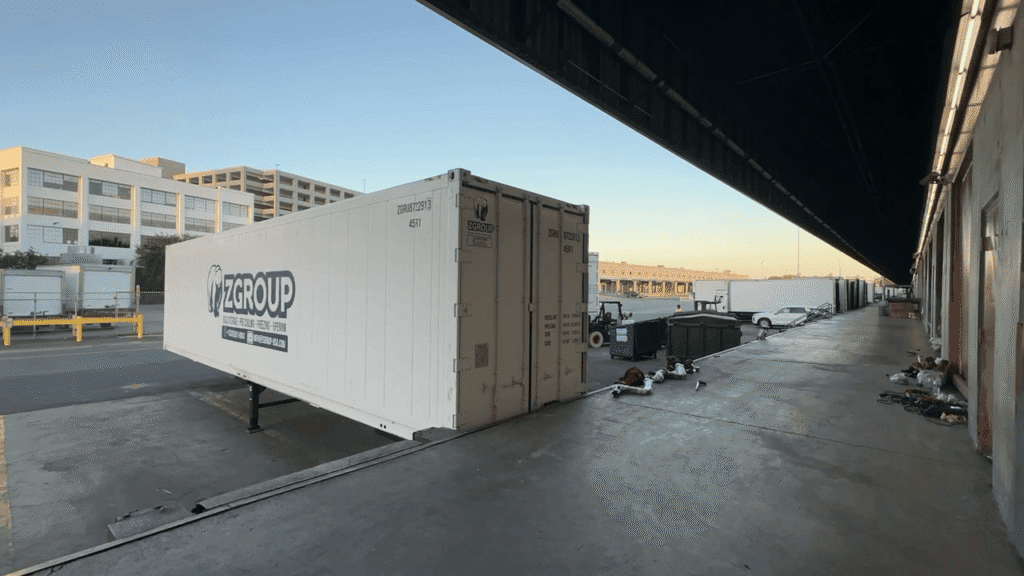

ZGROUP USA’s modular packinghouse offers a comprehensive solution tailored to the customer’s needs:

- Temperature-Controlled Reception and Loading area: Consisting of two containers with humidity control up to 95 percent, ensuring optimal conditions for product handling and storage.

- Advanced Pre-Cooling: Capable of cooling up to 10 pallets per batch to 35 degrees using air forced technology, reducing product temperature rapidly and efficiently.

- Spacious Cold Storage: Providing 960 square feet of storage with humidity control up to 95 percent, accommodating large quantities of product while maintaining freshness and quality.

The modular facility boasts an expandable design, comprising three similar blocks that allow for easy scalability to meet growing demand and changing requirements. This innovative approach enables rapid production and on-site installation completed in less than 45 days and just one week, respectively, a feat unattainable with traditional solutions.

The elevated installation on concrete beams eliminates the need for costly grading and paving, making it both cost-effective and eco-friendly. Additionally, the use of recycled shipping containers paired with new Thermo King refrigeration units significantly reduces the carbon footprint, promoting sustainability.

The facility is equipped with cutting-edge technology, including a Pre-Cooling unit monitored online via ZTRACK device, capable of cooling each pallet in under 30 minutes. Innovative engineering techniques, such as modified marine reefer units, ensure optimal cooling capacity and airflow, safeguarding product integrity through intelligent temperature adjustment.

“Our modular cooling facility is a game-changer for growers, offering unparalleled flexibility, efficiency, and quality control,” said Florent Philippot, CEO of ZGROUP USA. “By providing a turnkey solution that addresses the unique challenges faced by our customers, we empower them to enhance product quality, streamline operations, and capitalize on market opportunities without the complexities associated with traditional cooling facilities.”

The introduction of ZGROUP USA’s modular cooling facility underscores the company’s commitment to innovation and excellence in the cold chain industry. With a focus on sustainability, efficiency, and operational flexibility, ZGROUP USA continues to lead the way in delivering cutting-edge solutions that meet the evolving needs of its customers.

Publication date: Tue 26 Mar 2024

Author: © theproducenews.com