The global supply chain operates as the lifeblood of trade, with industries such as agriculture, seafood, poultry, and pharmaceuticals relying heavily on logistics efficiency. A crucial element driving the success of these industries is refrigerated storage containers—or “reefer containers.” These state-of-the-art temperature-controlled solutions play an indispensable role in maintaining the quality and safety of perishable goods as they traverse continents.

Today, the demand for refrigerated containers is surging, fueled by expanding global trade, advancements in technology, and changing consumer expectations around freshness and quality. But what makes reefer containers so essential? What innovations are shaping their future? This guide dives into these questions, offering valuable insights to logistics professionals, food distributors, and supply chain managers.

Understanding Refrigerated Storage Containers

What Are Refrigerated Containers?

Refrigerated storage containers, commonly known as reefer containers, are specialized shipping containers designed to transport perishable and temperature-sensitive goods. These include fresh produce, dairy, seafood, poultry, frozen goods, pharmaceuticals, and specialty chemicals. Equipped with refrigeration units, these containers maintain a controlled temperature range, ensuring the integrity of the cargo even during long-haul transportation.

Primary Purpose

The primary objective of these containers is to extend the shelf life of products, maintain their quality, and prevent spoilage. Whether it’s fresh lettuce destined for supermarkets or vaccines traveling across the ocean, reefer containers enable secure and seamless transportation, making them critical contributors to global trade.

Types of Refrigerated Containers

1. Standard Reefer Containers

The most commonly used reefer container, this type offers a range of temperature settings and is ideal for general perishable goods like fruits and vegetables.

2. Super Freezer Containers

Designed to maintain ultra-low temperatures, super freezer containers are essential for transporting goods like seafood, ice cream, or medical products that require consistent freezing at sub-zero levels.

3. Controlled Atmosphere (CA) Containers

These technologically advanced refrigerated units optimize the oxygen, carbon dioxide, and nitrogen levels to slow down the ripening of produce. Ideal for long-distance transportation, CA containers ensure fresh crops like apples or berries arrive in top condition.

Benefits of Using Refrigerated Storage Containers

Refrigerated containers present a wide array of benefits for businesses across industries. Here’s why they are indispensable in modern supply chains.

1. Extended Shelf Life

By maintaining ideal storage temperatures, reefer containers significantly extend the freshness of goods. This directly translates to reduced waste and higher profitability for growers, food distributors, and retailers.

2. Versatility in Transportation

Reefer containers are versatile enough to support multiple modes of transport—by sea, rail, air, or road—ensuring seamless door-to-door logistics solutions.

3. Cost Efficiency

While the initial investment in refrigerated transport may seem steep, the ability to prevent spoilage and maintain product integrity offsets these costs significantly. Businesses save money by reducing losses and satisfying their customers’ quality expectations.

Challenges Facing the Reefer Industry

Despite their valuable contributions, the refrigerated storage container industry faces several challenges.

1. High Initial Investment Costs

Reefer containers come with higher production and purchase costs compared to standard containers. Investing in fleets of these highly specialized units can pose a barrier for small to mid-sized enterprises.

2. Technical Maintenance

These units require regular technical maintenance to keep their refrigeration systems functioning optimally. Routine inspections and repairs are a must to avoid mechanical breakdown and safeguard the transported goods.

3. Environmental Impact

Given the energy-intensive refrigeration process, reefer containers have traditionally been associated with increased carbon emissions. This has raised concerns among environmentalists, pushing the industry toward finding eco-conscious alternatives.

The Future of Refrigerated Storage Containers

Despite these challenges, the future of reefer containers looks promising, thanks to technological advancements aimed at revolutionizing the cold chain.

Smart Refrigerated Containers (IoT)

IoT-enabled reefer containers allow real-time monitoring of temperature, humidity, and location during transit. This streamlined approach ensures seamless issue mitigation and provides critical transparency for supply chain managers.

Eco-Friendly Refrigerants

The evolution of sustainable refrigerants has paved the way for reduced environmental impact while maintaining efficient cooling capabilities. Businesses are increasingly adopting eco-friendly alternatives, such as hydrofluoroolefin (HFO) refrigerants, to reduce their carbon footprint.

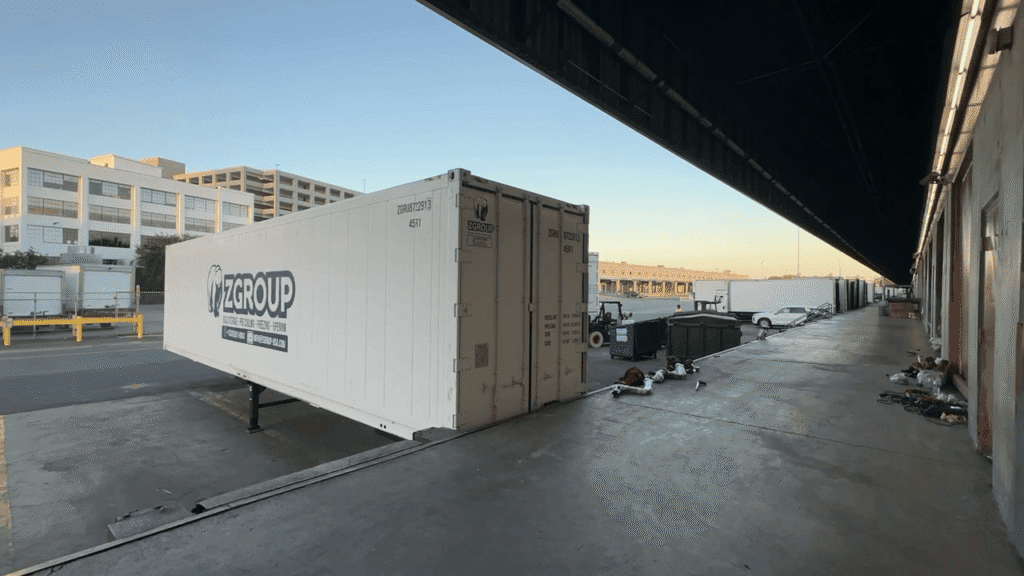

Modular Facilities for Cold Storage

Innovative solutions like modular cold storage facilities are rising in popularity. Leading players such as ZGROUP repurpose reefer containers for uses beyond transportation, transforming them into modular cold rooms, walk-in coolers, iqf freezer or fully integrated refrigerated facilities. These reusable designs address cold storage needs while minimizing construction costs.

ZGROUP’s unique offering allows containers to be merged into larger facilities, creating scalable and energy-efficient solutions tailored to specific business requirements—a game-changer for industries like agriculture and logistics.

Leveraging Refrigerated Containers for Your Business

Refrigerated storage containers are no longer optional in industries requiring precise temperature control. From preserving the freshness of food items to ensuring the viability of critical pharmaceuticals, reefer containers remain a backbone of global trade.

For businesses seeking flexibility, ZGROUP’s innovative approach to repurposing reefer containers provides unparalleled advantages in storage and transportation. Whether you’re a grower, distributor, or pharmaceutical provider, consider opting for modular and environmentally conscious options to better suit your needs.

Stay ahead of the curve. Explore how ZGROUP’s solutions can transform your operations and set new standards of efficiency and sustainability.