Doubling refrigerated storage capacity without adding power

In dense urban markets like Brooklyn, expanding cold storage capacity is rarely about finding more space. It’s about working within tight constraints – limited electrical capacity, fixed footprints, and short timelines.

A fast-growing meal-prep company serving direct-to-consumer customers was beginning to outgrow its existing refrigerated storage setup. As demand increased and fulfillment volumes rose, managing peak production periods became increasingly challenging.

The facility already relied on refrigerated containers for cold storage, but available power was maxed out. Upgrading the electrical infrastructure would have been expensive, time-consuming, and disruptive to ongoing operations.

When Cold Storage Becomes the Bottleneck

The operation was running with six individual refrigerated containers used for cold storage and freezer functions. While functional, the layout limited efficiency and restricted picking and staging space.

What the company needed wasn’t more containers – it was better cold storage design.

A Modular Cold Storage Solution

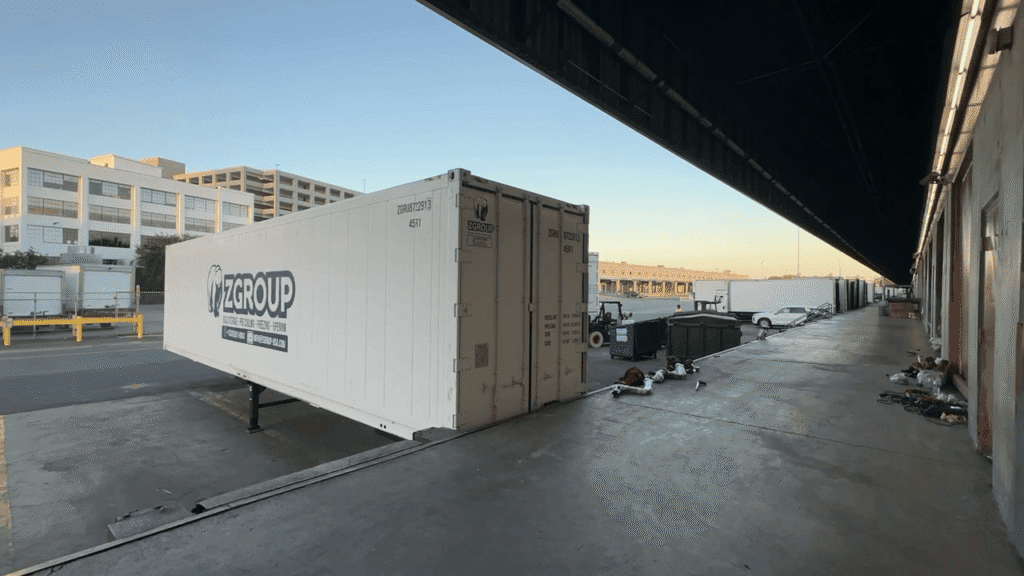

ZGROUP delivered a ZSTORE 12XL, a modular cold storage system built from three ZSTORE 4XL units, connected to function as one integrated refrigerated space.

By switching to ZSTORE XL, the operator was able to:

- Double cold storage capacity

- Maintain the same electrical requirement

- Reduce energy demand using low-amperage reefer units (16A)

- Create larger, more efficient picking and fulfillment areas

Designed for Short Lead Time and Peak Season

The system was delivered with a short lead time and installed without construction delays. Flexible rental terms allowed the company to scale storage capacity during peak demand without long-term commitment.

For urban food businesses, mobile cold storage and freezer solutions like ZSTORE XL offer a practical way to grow without overbuilding.